If playback doesnt begin shortly try. Immediately wrap each piece of plywood with resin treated fiberglass cloth and install the sticky mess on both sides of the transom and bolt it all into place with the nuts to the inside.

Moreover how do you strengthen a fiberglass boat.

How to reinforce a fiberglass boat transom. Immediately wrap each piece of plywood with resin treated fiberglass cloth and install the sticky mess on both sides of the transom and bolt it all into place with the nuts to the inside. Allow time to cure. Then seal the bolts let.

If the fiberglass skin is in good condition it is usually reused and glued back in place over the new core. The cuts made in the fiberglass skin to gain access are repaired with multiple layers of fiberglass cloth and epoxy. Limit the repair area.

Restoring boat exteriors to their original condition is expensive. This is probably the hardest part of the entire process. Removing the old transom and getting it down to a smooth flat surface ready for new plywood again.

I used a hammer and chisel small pry bar and the planer to get it out. Again you have to be very careful that you dont put too much pressure on the hull. The transom curve on your boat isnt very deep though bending in 34 stock will not be possible so youll bend in thinner stuff.

Its likely 38 will take the bend though you cuss a bit while 14 will easily bend but youll need more layers. For your needs two layers of 14 will do if well bonded and tabbed. If the boat had a single motor well and wide deck cap a cut through the cap or removal of cap would have probably been necessary to reach the entire inside of the transom.

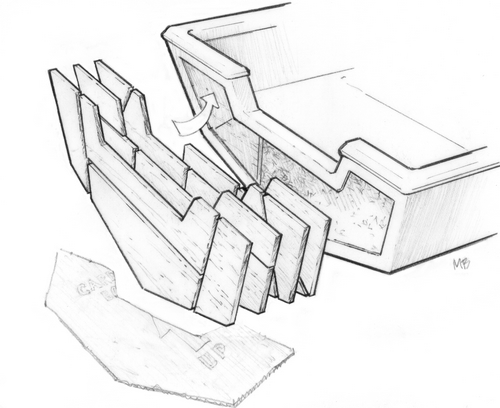

The next step in the rebuild is the removal of the old plywood. Feb 21 2006. How do you reinforce the fiberglass.

Well you really have to be carefull the tower is putting a lot of stress into a small area that was not designed for that. Every boat is different if that part has to much flex you would need to brace it from the floor any movement when your boarding will dammage the deck. How to rebuild the Transom on a Fiberglass Boat - YouTube.

How to rebuild the Transom on a Fiberglass Boat. Fiberglassing A Composite Boat Transom. Fiberglassing A Composite Boat Transom.

If playback doesnt begin shortly try. Measure the thickness of your transom. Remove the top rail of the transom with the screwdriver.

Use the hammer and chisel to remove all the wood reinforcements and the fiberglass core. When you are finished your transom should have the appearance of an empty envelope waiting to be filled with reinforcing material. How do you reinforce a fiberglass transom.

Rough up the edges of the outer fiberglass skin you removed from the transom with the palm sander. Apply a heavy coat of epoxy to the last sheet of plywood you used to fill the transom void and replace the outer fiberglass skin of the transom using wood screws around the edges to attach the fiberglass to the plywood. The average cost of transom windows is between 200 to 575 per window set.

Transom windows are often installed at the same time as a new door installation so window replacement is usually more common than installing new transom windows alone. Do fiberglass boats have wood in them. Most fiberglass boats have wood in them.

How to make a boat transom. Now I am not saying this is the right way or wrong way to make a boat transom. This is just how I decided to make it.

How to reinforce a transom on an aluminum boat. If you are noticing soft spots on the transom of your aluminum boat you will definitely need to reinforce your transom and sooner rather than later. You will need to do a bit of research to determine the best course of action but in general you will need either plywood or metal some people.

How should I reinforce my transom. So I have a 1979 thunderbird TriHull with a Mercury inline 6 outboard motor on it. There is crack in the fiberglass on the inside of the transom running from one of the lower mounting bolts for the engine bracket to the other.

The new motor is much heavier than the Gamefisher motor. I need to reinforce the transom. I can see where it is puting a lot of stress on the original small knee brace.

I am looking for some info on where to purchase a new knee brace and the corner brackets that I can mount on the corners on the top of the transom for additional support. - the stringers were bedded with thicker fiberglass mat to the bottom of the boat and to the transom. I used a slightly thicker mix of resin to fill and hold in the gaps and imperfections between the boat transom and layers of the stringers.

- stringers were fiberglassed with 2 layers to cover exposed wood. Moreover how do you strengthen a fiberglass boat. Cut fiberglass sheets to fit over the weak areas in the fiberglass and any other area that you want to reinforce.

Apply resin to the surface with a paint brush. Press the fiberglass sheets into the resin. Apply a second layer of resin over the fiberglass sheets.

Additionally how much does transom repair cost. Put on a thick coat of your epoxy on the very last plywood sheet to fill the void on the transom. Then replace the transoms external fiberglass skin with wood screws placed on the edges.

You should be able to attach the plywood and the fiberglass together. Drill the required holes on the plywood. Put on more epoxy to the fiberglass skins edges.

The caused the boat to take on larg. A few months ago I capsized my 17ft Sailboat. In doing so the rudder twisted and cracked the transom at the lower pintle.

Wrapping Up the Installation. Installing A Transducer On Fiberglass Boat. Setting Out the Cable.

When its Possible to Cut the Transducer Cable.